We are cable management experts and yet our telecom rack looked like this. What a mess.

This is a small example, but server rooms are far more complex and often have miles of wiring. With 5G refits really starting to gain pace, it could be a good time to take a look.

Left unmanaged (as it was here), disorganization can creep in until it becomes really hard to track and maintain your network.

We have seen that the more people are involved, the more disorganized things can become unless you standardize and regulate how the wiring is meant to be set up. Changing behavior may be your biggest challenge.

This unstructured cabling can lead to a range of problems. It can make finding the right wiring to check, troubleshoot or overhaul a day long quest as you might face totally disorganized cables, blocking sight lines, lying in corridors, and even decreasing airflow which can lead to heat issues – some might even be too close to moving parts (or whiteboards).

Plus your fiber is being exposed to macrobends that can compromise the data flowing through the system. Not good. Try troubleshooting that!

So what did we do?

Our IT group used our Fast-Drop™ Rack Mount Fiber Array Panels which are preassembled with our own patented Radius Control Modules (RCM’s) which reduce macrobends. Combined with our own hook and loop product, this brought order to the chaos.

The morale of the story is that it happens to everyone to some degree – even us.

But better cable management gives you better performance, easier traceability, less heat issues, better safety, looks so much better and lets you manage /troubleshoot and refit racks far more easily.

The arrays work well and made the whole process fast and efficient. They attach to the rack with a fastening bar.

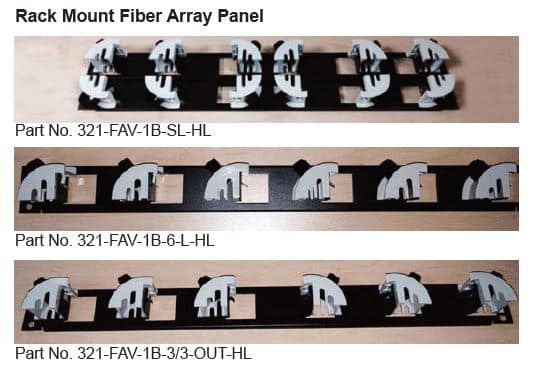

In this case we created a custom array configuration which speaks to the versatility of the array…it can be adapted to fit what you need; however the 3 most commonly demanded configurations are shown in the images below.

The core component the Fast-Drop Radius Control module was developed to prevent data loss from macro-bends. It provides the BICSI recommended minimum bend radius for fiber optic cables. Used as a standalone component, it speeds up refits and cabling rework because it clips on simply, easily and quickly to standard racks.

Applications and Uses:

- Fiber – FTTH or FTTP cabling

- Patch panels, control boxes

- Racks, cabinets, and enclosures

- Data centers/central

- Telecom switches and base stations

- Medical, x-ray, and imaging equipment

- Industrial equipment, Electrical wiring,

- Hydraulic, pneumatic and tubing/hoses

Find out more about Fast-Drop pre-assembled arrays

Find out more about Fast-Drop RCM’s