Krono-Resist HT Series™ magnet wire allows your HEV/EV motor to run at higher temperatures and in more extreme environments. The solution to high temperature motor windings, this product increases heat transfer, allowing greater design flexibility and long term performance.

- Withstands higher temperatures to 265℃ by dissipating heat faster than regular magnet wire.

- Motors can run hotter, longer, with less risk of damage to the wire.

- More conductive material in the same space yields a higher power density creating longer drive times or reducing the battery size needed.

Features:

- Higher heat resistance to 265℃ – best in the industry- increases the motor power density – so can be used on higher temperature applications like variable speed drives.

- Faster heat transfer with less “enamel” – improves the heat transfer coefficient by 2-3x vs standard Polyimide enamel coating.

- Protection against partial discharge and detrimental corona, both long standing problems in this arena.

- Protection against electrical breakdown and short-circuiting.

- The durable coating resists breakage during coil winding.

Applications:

- Applications that need to perform in high temperatures or require improved power density to minimize size and weight.

- HEV/EV motors, Automotive, Aviation/Aerospace, Military/Defense, Oil & Gas and Transportation.

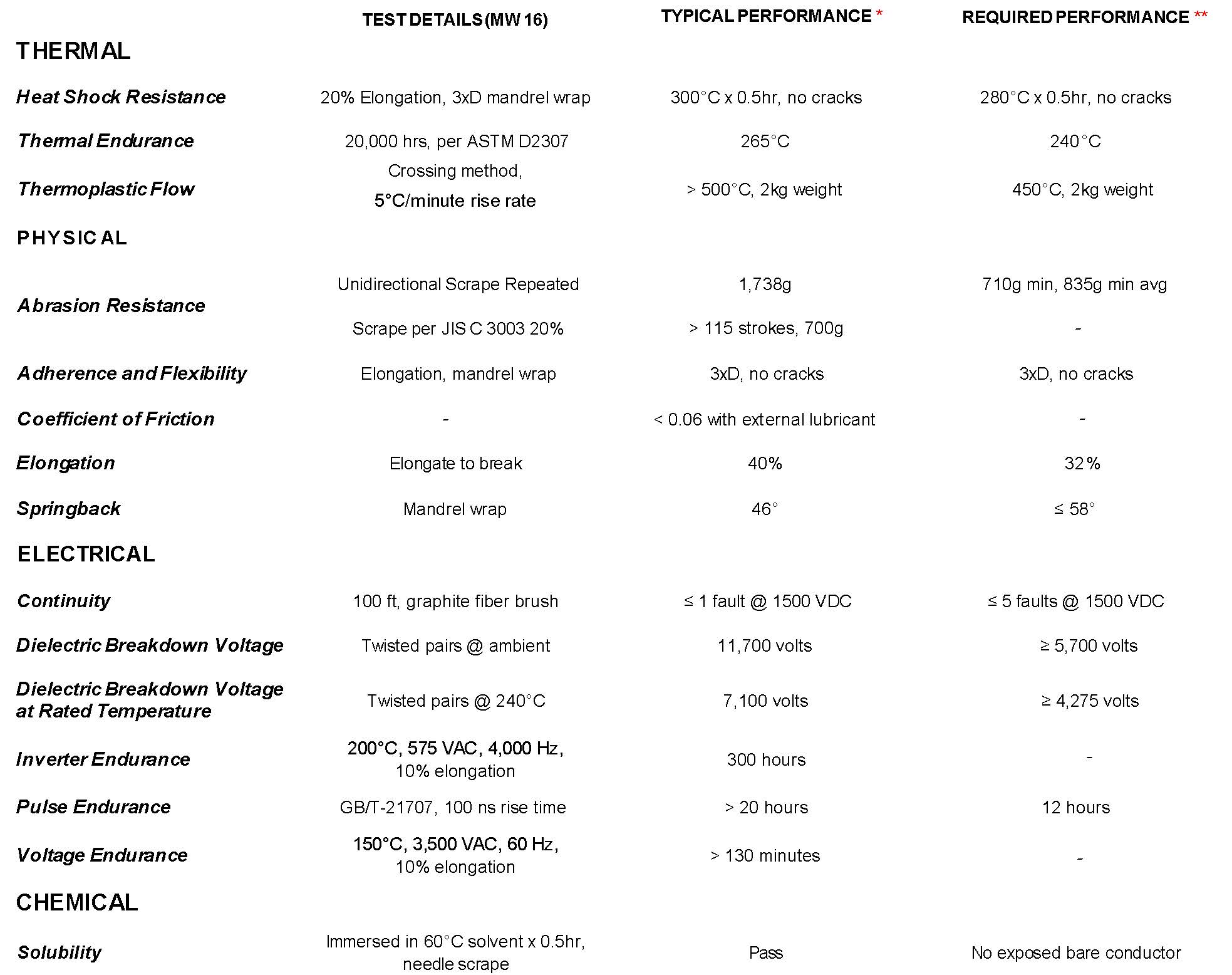

Thermal Endurance: 265°C when tested per ASTM D2307

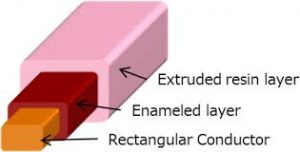

Conductor: Copper

Shape: Round or square or rectangle

Insulation Material: Polyimide/Polyamide-imide

Size Range: 12-24 AWG Heavy Build (Square or Rectangular)

Thermal Endurance: UL 260°C listing. Thermal Endurance of 265°C per ASTM D2307.

…………………………Highest market temperature rating for Polyimide/Polyamide-imide constructions.

Heat Shock: Exceeds NEMA MW 16 with 300°C

Thermoplastic Flow: Exceeds typical enamel systems and most thermoplastics

Windability: High windability due to internal lubrication while retaining excellent property retention

Electrical: Excellent resistance to partial discharge and Corona effect even after elongation caused by winding.

Life Expectancy Nano particle enamel system increases life expectancy despite non-sinusoidal waveforms (inverter apps) even at elevated temperatures.

Chemical: Resistant to petroleum naphtha, toluene, ethanol, 5% sulfuric acid, 1% potassium hydroxide, butyl acetate, acetone for 24 hours at RT.

Stripping Method: Non-solderable – must be mechanically stripped before soldering, or terminated by means of insulation piercing terminals.