Spring-Fast Aerospace Grommet Edging: Aero

The BAP Aerospace Flexi-Grommet™ Series protects wires and cables from chafing and arcing.

Key Benefits

- Superior performance: encapsulated spring steel core outperforms plastic grommets.

- Snap on installation lowers costs 49% vs. grommets with glue. Watch the 4 min. video below.

- Improves efficiency 9.5x – due to fewer steps in workflow.

- BAP Substrate is encapsulated with lubricious fusion bonded EPOXY for superior abrasion and chemical resistance.

- Polymer cushion providing a sacrificial soft interface for cables to protect against abrasion.

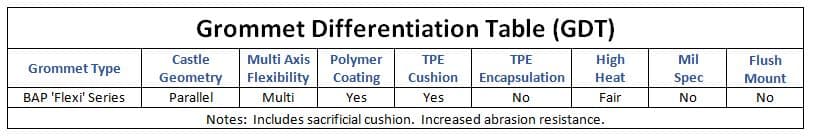

- Greater gripping strength for severe shock and vibration environments with 4-axis flexibility.

Features

The old nylon grommet with glue is old, inefficient and costly. DTi has a better way.

- Encapsulated with a steel substrate

- Snaps on in seconds with finger pressure cutting total install costs by 49%

- Installs continuously and is very flexible for use on straight edges and sharp inside and outside corners

- Self locking with strong retention

- 2- or 4-axis flexibility fits single/multi-plane applications including small inside/outside radii

- Chemically resistant to most hydrocarbons, Skydrol immersion, salt spray, shock and vibration resistance

- Across the product life cycle its ease of application, use and removal will consistently save time and money

- Customization available

Spring-Fast Process Benefits

- Significant reduction in installation steps and time

- No special handling, training or special gear

- No toxic adhesives/VOCs – a green solution with no clean up or Haz-Mat issues

- No fixturing during curing

- No delays waiting for the adhesives to cure

- No long term embrittlement of the nylon grommet itself

- No adhesive degradation over time

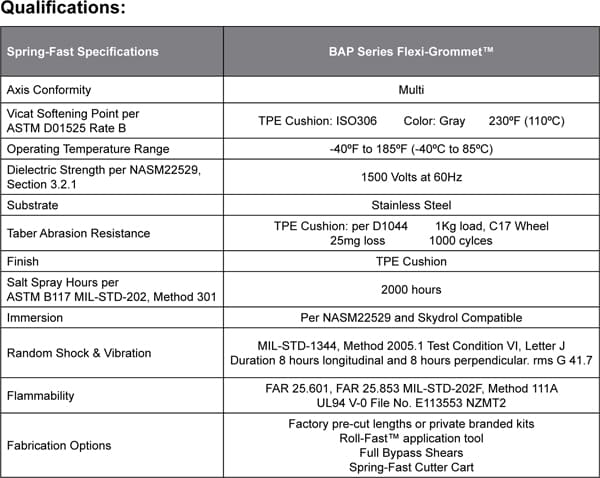

Key Specifications

- Heat continuous to 185°F (85°C)

- Low Temperature to -40°F (-40° C)

- High Corrosion Resistance

- UL94 V-0 Flammability Rating

- Superior Dielectric Strength

- High Shock and Vibration Resistance to rms G 41.7

- Continuous Edge Protection on Flanged Holes, 1/8″ (3.2 mm) or greater inside radius and 1/4″ (6.4 mm) or greater outside radius

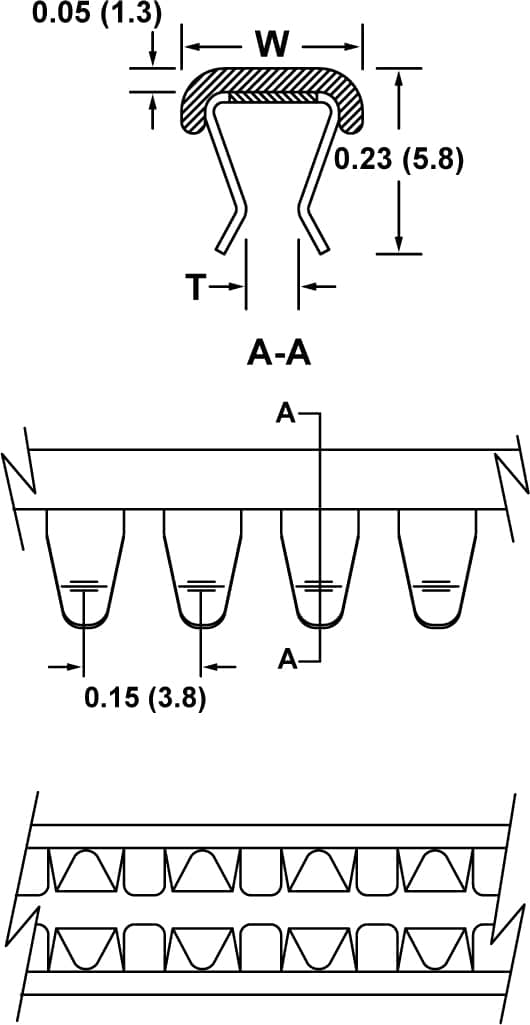

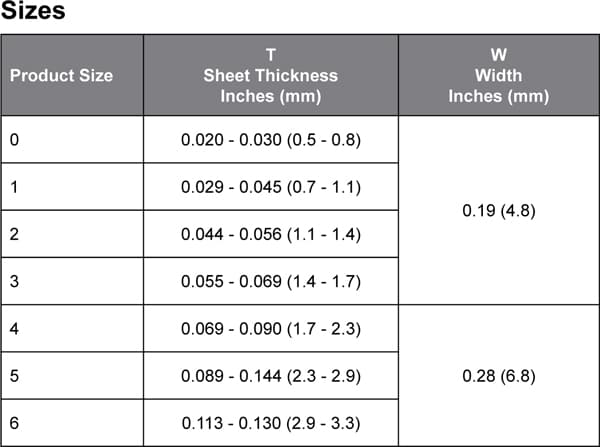

- Sheet Thickness 0.02” (.5 mm) to 0.25” (6.4 mm)

- Factory discrete cut lengths or some factory precut lengths of:

-25 ft. (7.6 m)

-100 ft. (30.5 m)

-500 ft. (152 m) - Roll-Fast™ installation roller

- Full by-pass shears for burr free cut

- Spring-Fast cutter cart

- Customization/private branded kits are available