Industries & Applications

Production Processes

Device Technologies offers assorted processing capabilities and disciplines both as a product development partner as well as service. We work daily with disciplines that include and are not limited to Precision stamping, metal forming, fabrication and roll forming to injection and insert molding, thermoplastic and rubber molding, vulcanization and extrusion, linear polymer coating, Related secondary processes supporting customer handling and assembly needs including cutting to length, kitting, specialty packaging and other ergonomic considerations that today's demanding production lines require.

DTi has global distribution capabilities, servicing OEMs and Fabricators in the following markets to name a few:

Aerospace

Aerospace- Military Electronics

- Business & Banking Equipment

- Computers & Storage Technology

- Food Service and Baking Equipment

- HVAC & Lighting

- Instrumentation and Testing

- Medical & Imaging Systems

- Power Supplies & Backup Systems

- Telecommunication Systems Equipment – Access, Switching, Transmission, Routing

- Gaming and lottery transactions

- Railroad

Device Technologies on the Fast Track with Two New Collaborative FEA (CFEA™) Rail Solutions

This past year, DTi leveraged its FEA capabilities to help develop not one, but two new rail sealing solution requirements, for two different OEM’s.

Collaborative and Custom Design Engineering Service

In response to a customer's request, DTi developed a Custom Fiber Optic Radius Control Module (RCM) that simply snapped into the customer's plenum.

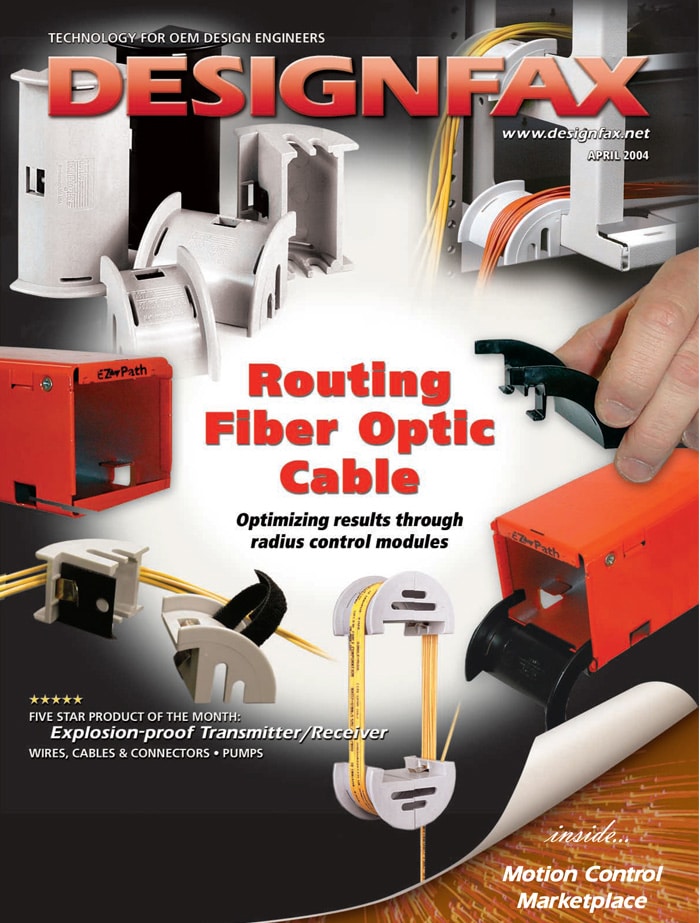

DTi Featured in DESIGNFAX

Routing Fiber Optic Cable

Optimizing results through radius control modules

Conquer Wire Chafing: The Short Guide to Caterpillar Grommets

Wire chafing is a common issue that can lead to severe problems such as data loss, functionality issues, and the risk of arcing and fires. This is where caterpillar grommets come into play, protecting wires and cables from chafing and arcing. In this guide, we'll...

DTi Saves OEMs Money & Time: Do More With Less – by Switching 1 Component

Who doesn’t want to cut costs and improve efficiciency? Particularly in these times of supply chain stress, inventory holding costs rising, price increases, and the drive to do more with less as staff shortages bite. How would you like to cut a cost in half AND do...