Spring-Fast NASM22529 Overview

Cage Code: 0HES0

Spring-Fast Mil Spec Grommets protect wires and cables from chafing and arcing.

Key Benefits

- Superior performance: Spring-Fast outperforms nylon MS21266 & BACG20Z grommets.

- Snap on installation lowers costs 49% vs. grommets with glue. Watch the 4 min. video below.

- Improves efficiency 9.5x due to fewer steps in workflow

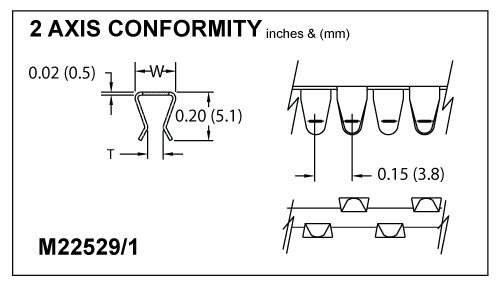

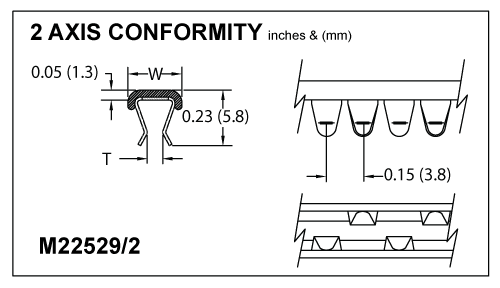

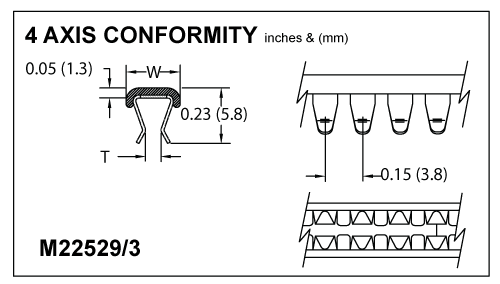

- 3 variants: for 2 or multi axis flexibility

Grommet Differentiation Table (GDT)

| Grommet Series | Castle Geometry | Flexibility | Polymer Coating | Extra Cushion | 100% TPE Encapsulation | High Heat | Mil Spec | Application Method | Notes |

|---|---|---|---|---|---|---|---|---|---|

| NASM22529/1 | Alternating | 2 axis | Yes | No | No | 285°F/140°C | Yes | Snap on/No adhesive | FAA Approved No cure time delay |

| NASM22529/2 | Alternating | 2 axis | Yes | Yes | No | 185°F/85°C | Yes | Snap on/No adhesive | FAA Approved No cure time delay |

| NASM22529/3 | Opposing | Multi-axis | Yes | Yes | No | 285°F/140°C | Yes | Snap on/No adhesive | FAA Approved No cure time delay |

| FOR REFERENCE | |||||||||

| MS21266 Nylon | Opposing | 2 axis | NA | Yes | NA | 257°F/125°C | Yes | Adhesive Required | 8-24hr cure time delay |

| MS21266 Teflon | Opposing | 2 axis | NA | Yes | NA | 527°F/275°C | Yes | Adhesive Required | 8-24hr cure time delay |

Applications

Military use – in service worldwide on fighter jets, helicopters, transports, ships, tactical equipment, C4 electronics & ground-based missile systems

Commercial use – general aviation aircraft, business jets & related avionics & electronic systems

- Airframe Structure

-Lightening Holes

-Wing Ribs

-Tail Section

-Bulkheads

- Tactical Vehicles

- Auxiliary Power Units

- Avionic Instruments

- Seating

- Dashboards

- Radar Systems

- Flight Refueling

Features

Spring-Fast is superior to the old inefficient, costly nylon grommet with glue.

- Snaps on in seconds with finger pressure cutting total install costs by 49%

- Encapsulated steel substrate locks onto the edge with proven retention

- 2- or multi-axis flexibility fits single/multi-plane applications and small inside/outside radii

- New NASM22529/3 has multi axis flexibility –perfect for flanged edges, lightening holes & penetrations

- Chemically resistant to most hydrocarbons, Skydrol immersion, salt spray, shock & vibration resistance

- Installs continuously and can be used on straight edges, holes and small inside and outside corners

- U.S. Dept. of Defense and FAA approved per NASM 22529/1, NASM 22529/2, NASM 22529/3

- National Stock Numbers per Federal Supply Code 5325.

- Customization available

Spring-Fast Process Benefits

- Significant reduction in installation steps saving time & money

- No special handling, training or equipment

- No toxic adhesives/VOCs – a green solution with no clean-up or Haz-Mat issues

- No fixturing or waiting for the adhesive to cure

- No embrittlement of the nylon grommet or adhesive over time

Key Specifications

- NASM22529 qualified FAA approved

- NAVAIR per 01-1A-505-1 (NASM22529/2 & NASM22529/3)

- RoHS compliant

- Temperature Range -40ºF to 185ºF (-40ºC to 85ºC)

- Flammability FAR 25.601, FAR 25.853, MIL-STD-202F

- Voltage Breakdown 60 Hz 1500 V

- Salt Spray Testing MIL-STD-202F

- Sheet thickness 0.02” (.5mm) to 0.25” (6.4 mm)

- Available in custom cut lengths & factory pre-cut reels of 25 ft. (7.6 m), 100 ft. (30.5 m) or 500 ft. (152 m)

- Tools available: Installation roller, full by-pass shears, castle removal, measuring scale, go/ no-go sizing gauge

- Customization/private branded kits available

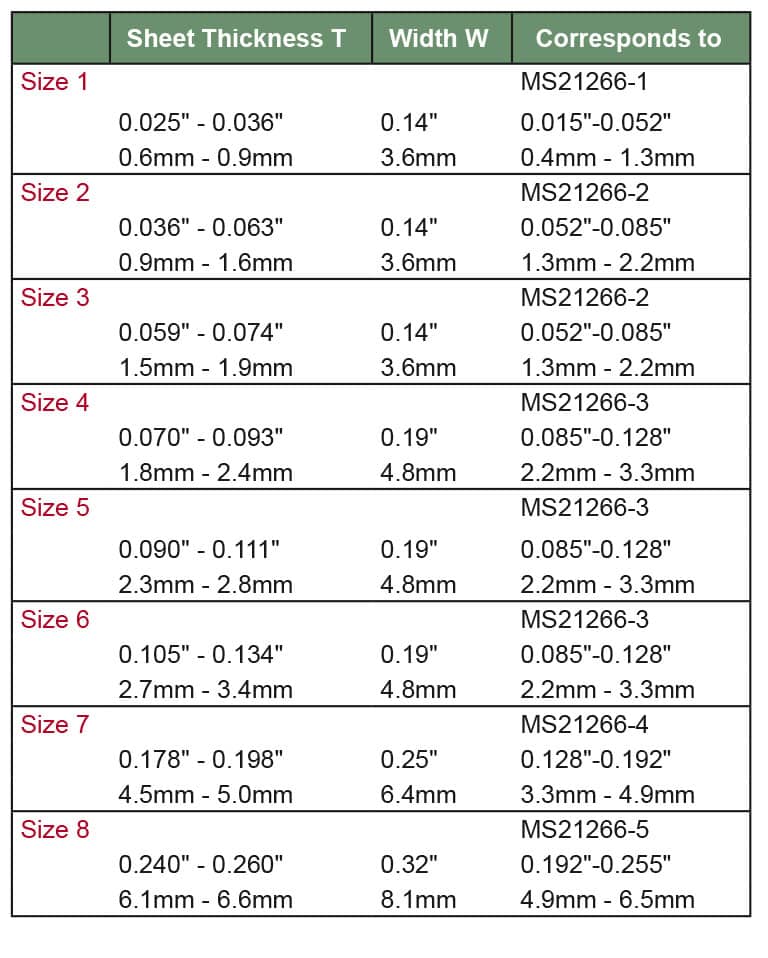

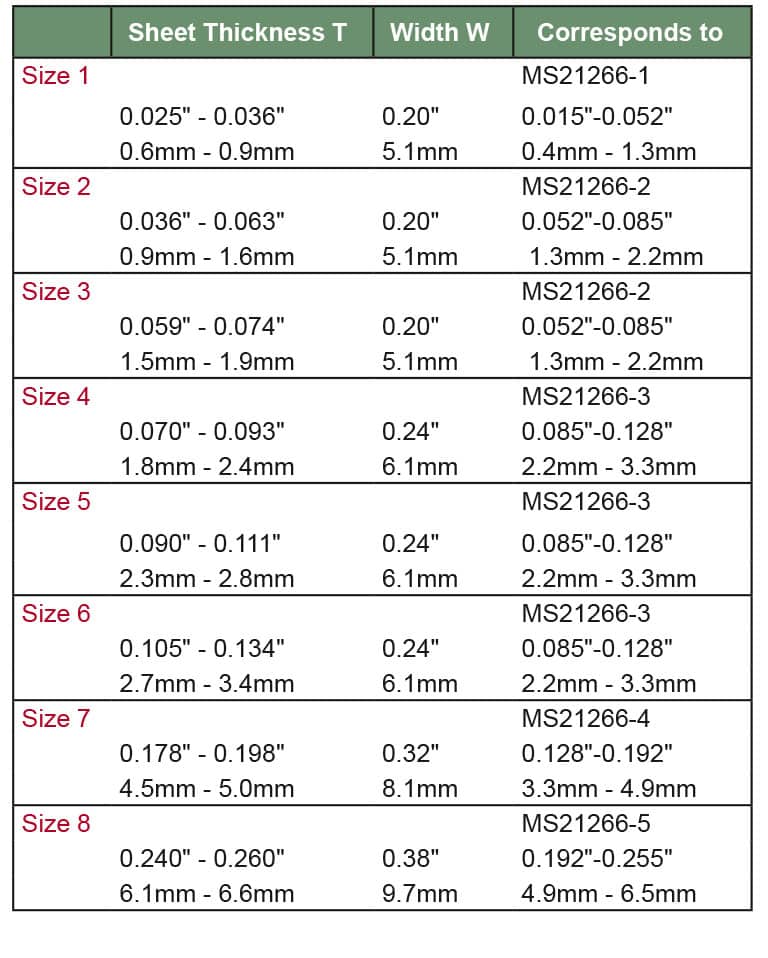

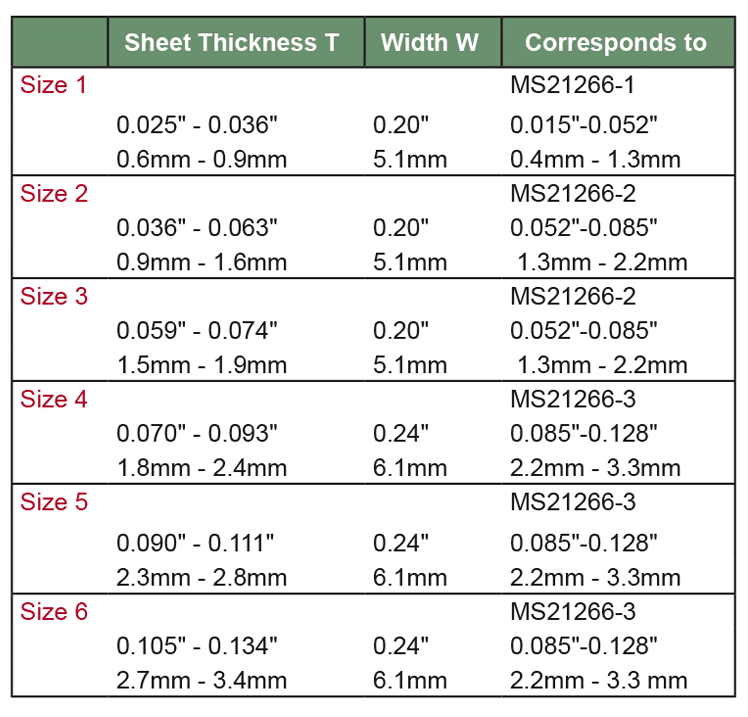

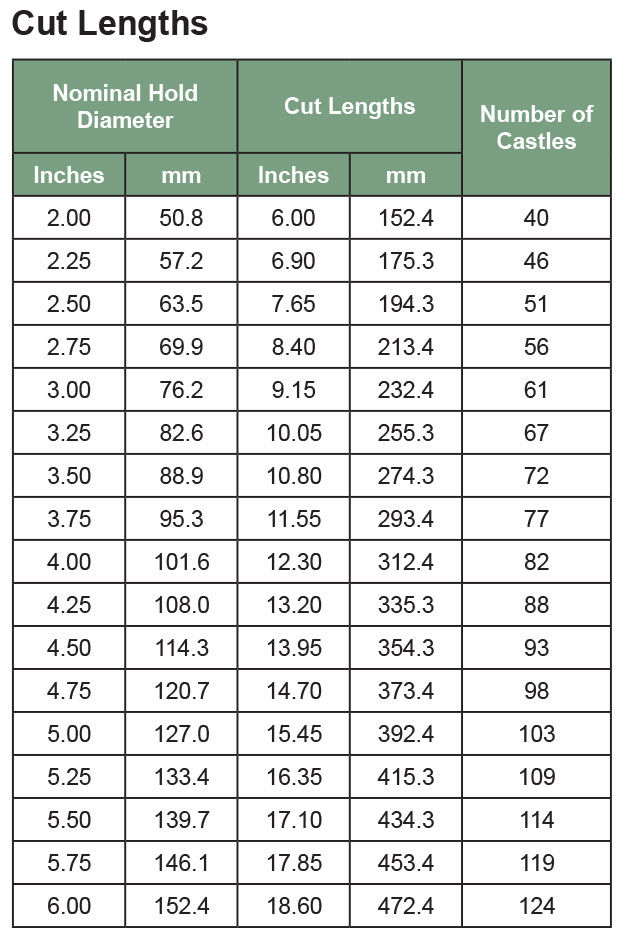

Sizing Charts

Due to sheet thickness tolerances and finishes, end user should determine product sizes by trial. When sheet thickness is at the maximum for the grommet chosen, end user may use a rubber mallet to set, or try the next size larger grommet.

Qualifications

| Spring-Fast Product Configurations | Mil-Spec /1 | Mil-Spec /2 | Mil-Spec /3 |

|---|---|---|---|

| Axis Conformity | Single | Single | Multi |

| Vicat Softening Point per ASTM D01525 Rate B | Substrate Finish: ISO306 356ºF (180ºC) | TPE Cushion: ISO306 230ºF (110ºC) | TPE Cushion: ISO306 230ºF (110ºC) |

| Operating Temperature Range | 285°F (140°C) | 185°F (85°C) | 185°F (85°C) |

| Dielectric Strength Volts 60Hz NASM22529 Section 3.2.1 | 1000 | 1500 | 1500 |

| Substrate | Stainless Steel | Stainless Steel | Stainless Steel |

| Taber Abrasion Resistance | Substrate Finish: Epoxy Per ASTM D 1044 1 kg load, C17 Wheel 8 mg loss 5000 cycles | TPE Cushion: Per D1044 1 kg load, C17 Wheel 25 mg loss 1000 cycles | TPE Cushion: Per D1044 1 kg load, C17 Wheel |

| Finish (End Code) | Coating: Thermosetting Epoxy, Color: Lime Green per FED-STD 595, Color Number 14533 | Coating: Thermosetting Epoxy, Color: Lime Green per FED-STD 595, Color Number 14533 | |

| Salt Spray Hours | 500 ASTM B117, MIL-STD-202, Method 301 | 500 ASTM B117, MIL-STD-202, Method 301 | 500 ASTM B117, MIL-STD-202, Method 301 |

| Immersion | Per NASM22529 and Skydol Compatible | Per NASM22529 and Skydol Compatible | Per NASM22529 and Skydol Compatible |

| Random Shock and Vibration | MIL-STD-1344, Method 2005.1 Test Condition VI, Letter J Duration 8 hours longitudinal and 8 hours perpendicular, rms G 41.7 | MIL-STD-1344, Method 2005.1 Test Condition VI, Letter J Duration 8 hours longitudinal and 8 hours perpendicular, rms G 41.7 | MIL-STD-1344, Method 2005.1 Test Condition VI, Letter J Duration 8 hours longitudinal and 8 hours perpendicular, rms G 41.7 |

| Flammability | UL94 V-0 File No. E113553 NZMT2 • MIL-STD-202F, Method 111A | UL94 V-0 File No. E113553 NZMT2 • MIL-STD-202F, Method 111A | UL94 V-0 File No. E113553 NZMT2 • MIL-STD-202F, Method 111A |

| Fabrication Options | Pre-cut lengths. Bulk or private brand kits. Installation tool kit | ||

| Cross Reference Chart for NSNs & NATO Part Numbers | Cross Reference Chart for NSNs & NATO Part Numbers | Cross Reference Chart for NSNs & NATO Part Numbers | |