Spring-Fast Military: New NASM22529/3 Series

Cage Code: 0HES0

The new Mil Spec NASM22529/3 Series protects wires from chafing and arcing and is specifically designed for flanged holes/penetrations.

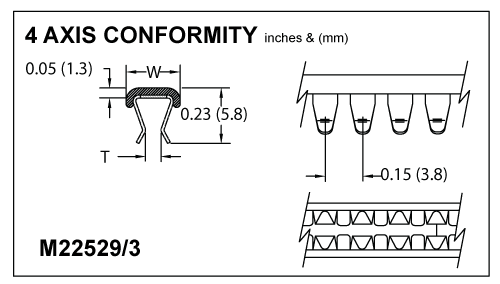

- NASM22529/3 – Opposing castles

- Added sacrificial abrasion cushion

- Multi Axis for flanged edges

Key Benefits

- New NASM22529/3 has multi axis flexibility –perfect for flanged edges, lightening holes & penetrations

- Superior performance: Spring-Fast outperforms plastic grommets.

- Snap on installation lowers costs 49% vs. grommets with glue. Watch the 4 min. video below.

- Improves efficiency 9.5x – due to fewer steps in workflow.

Grommet Differentiation Table (GDT)

| Grommet Series | Castle Geometry | Flexibility | Polymer Coating | Extra Cushion | 100% TPE Encapsulation | High Heat | Mil Spec | Application Method | Notes |

|---|---|---|---|---|---|---|---|---|---|

| NASM22529/3 | Opposing | Multi-axis | Yes | Yes | No | 285°F/140°C | Yes | Snap on/No adhesive | FAA Acceptable No cure time delay |

| FOR REFERENCE | |||||||||

| MS21266 Nylon | Opposing | 2 axis | NA | Yes | NA | 257°F/125°C | Yes | Adhesive Required | 8-24hr cure time delay |

| MS21266 Teflon | Opposing | 2 axis | NA | Yes | NA | 527°F/275°C | Yes | Adhesive Required | 8-24hr cure time delay |

Features

Spring-Fast is superior to the old inefficient, costly nylon grommet with glue.

- NASM22529/3 has 4-axis flexibility to fit flanged holes/penetrations

- Snaps on in seconds with finger pressure cutting total install costs by 49%

- Encapsulated steel substrate locks onto the edge with proven retention

- Multi-axis flexibility fits single/multi-plane applications and small inside/outside radii

- Chemically resistant to most hydrocarbons, Skydrol immersion, salt spray, shock & vibration resistance

- Installs continuously and can be used on straight edges, holes and small inside and outside corners

- Customization available

Spring-Fast Process Benefits

- Significant reduction in installation steps saving time & money

- No special handling, training or equipment

- No toxic adhesives/VOCs – a green solution with no clean-up or Haz-Mat issues

- No fixturing or waiting for the adhesive to cure

- No embrittlement of the nylon grommet or adhesive over time

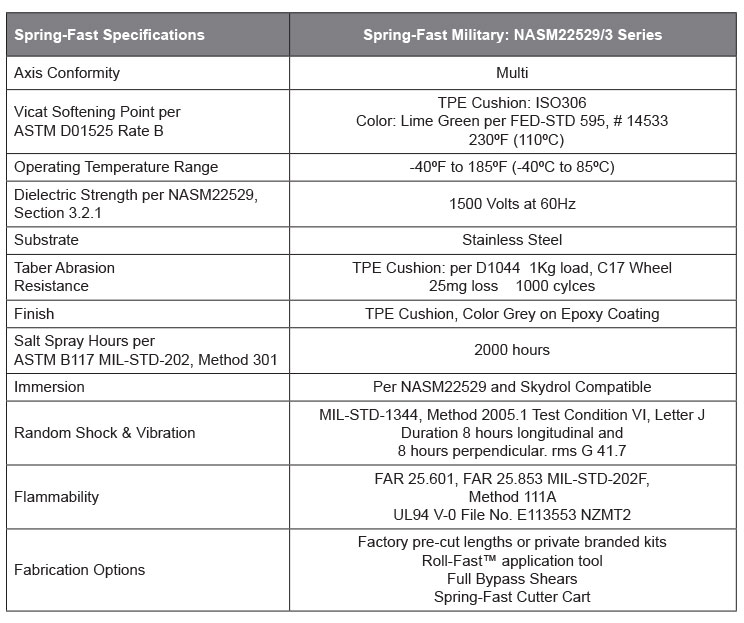

Key Specifications

- Heat continuous to 185°F (85°C)

- Low Temperature to -40°F (-40° C)

- High Corrosion Resistance

- Superior Dielectric Strength

- High Shock and Vibration Resistance to rms G 41.7

- Continuous protection on flanged holes,

- Corners: 1/8″ (3.2 mm) or greater inside radius and 1/4″ (6.4 mm) or greater outside radius

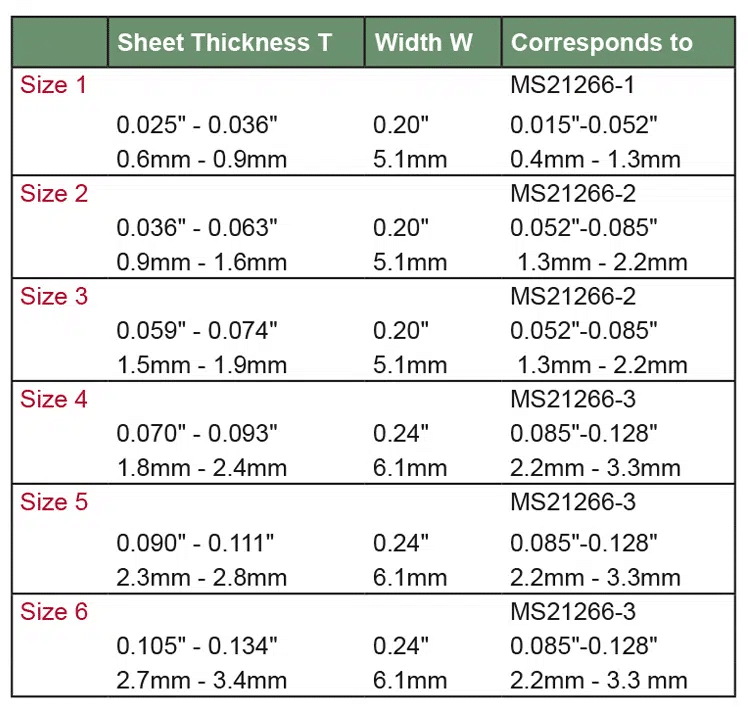

- Sheet Thickness 0.02” (.5 mm) to 0.25” (6.4 mm)

- Available in custom cut lengths & factory pre-cut reels of 25 ft. (7.6 m), 100 ft. (30.5 m) or 500 ft. (152 m)