Southborough, Ma. – July 31, 2013 – Commercial airplane manufacturers and aerospace engineers, who need protection against mid-air malfunctions, depend on Device Technologies FAA-approved grommet and FAR-compliant cable wrap to protect the wiring of critical jetliner components.

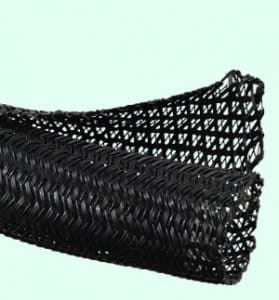

Spring-Fast® Wire Protection Grommet Edging and Protect-Fast™ Braided Wrap secure and optimize the performance of critical electrical systems.

FAA-Approved Spring-Fast® grommet edging Protect-Fast™ cable wrap

A global leader in wire protection solutions, DTi produces Spring-Fast grommet edging and Protect-Fast cable wrap offering high performance, quality, and reliability to commercial airframe manufacturers, whose cable systems cannot be compromised by accidental wire crimping and abrasion.

“The proper function of electrical systems is crucial to commercial airline safety and integrity,” said Nick Petri, President, Device Technologies. “We developed FAA-approved grommet and FAR-compliant cable wrap, specifically for use in airplane manufacture, providing reliable, long-lasting wire protection that meets high standards.”

The FAA-approved grommet provides greater gripping strength for severe shock and vibration environments, crucial to limiting wear on electrical wires and cables. What’s more, Device Technologies cable wrap provides an easy-to-assemble wire protection solution that’s used throughout the aircraft industry. The grommet fastens to the chassis and the cable wrap installs onto the cable harness.

In particular, Spring-Fast grommet offers advantages for commercial airplane manufacturers:

Easy to install

Locks to aircraft chassis with finger pressure in seconds

Eliminates the use of solvents, adhesives, ancillary materials and volatile organic compound (VOCs) associated with classic Nylon grommet strips; offers improved grommet reliability

Designed for high-shock, high-vibration environments

About Device Technologies, Inc.

Device Technologies, Inc. (DTi) designs, manufactures, and sells specialty fasteners to a broad spectrum of industries. Founder, Hector D. Petri, Technical Director, introduced the company’s first patented Spring-Fast® High Performance Grommet Edging in 1984. This product line, and resulting extensions, has grown significantly, serving a broad spectrum of industries including Aerospace, Department of Defense, Computer Servers, IT/Data storage, Gaming, HVAC, NASCAR, Semiconductor, Manufacturing and Transportation. DTi’s work in these industries has enabled the company to provide high performance, economical product solutions that include a variety of advance protection materials: Fast-Drop™Fiber Optic Radius Control Modules, Seal-Fast™ Edge Seals, Trim-Fast™ Edge Trims, Protect-Fast™Cable Management and sleeving solutions and Shield-Fast™ EMI/RFI gaskets and related RF Absorber and Thermal Management materials.

DTi’s growth in the specialty fastener industry has created the Advanced Technology Division (ATD) within the company that specializes in fully automated, linear and selective polymer coating. This innovative polymer coating process is a solution applicable to cable, wire, flat wire, stampings and profile metal formed products encapsulated in a broad range of thermo-plastic and thermo-setting resins.

DTi continues to invest in R & D to enhance opportunities for its product and process technologies, in compliance with ISO 9001 and AS 9100 standards. More information is available at the company’s web site, www.devicetech.com or call (508-229-2000).

Spring Fast®, Fast-Drop™, Trim-Fast™, Seal-Fast™, Protect-Fast™ and Shield-Fast™ are registered trademarks of Device Technologies, Inc.

Customer Contact:

Customer Service

Device Technologies, Inc.

(800) 669-9682

+1-508-229-2000

customerservice@devicetech.com

Technical Contact:

Steven O’Loughlin

Device Technologies, Inc.

+1-508-229-2000 Ext. 250

soloughlin@devicetech.com