Sooner or later you will want to upgrade your network which will include the wiring and the multiple racks and chassis you have installed over time.

One factor making this happen faster is 5G.

5G is opening up new business models with the convergence of wired and wireless networks. From what we see and hear, quite a few companies are reorganizing around this concept, breaking down traditional segments within their company as formerly separate businesses come together.

As well as 5G, the constant drumbeat of improving technology plus the constant thirst for fast data access in real time all combine to create the consistent level of upgrades we are seeing in data centre infrastructures.

As well as 5G, the constant drumbeat of improving technology plus the constant thirst for fast data access in real time all combine to create the consistent level of upgrades we are seeing in data centre infrastructures.

Yet the pain of upgrading networking panels and racks can be high. It’s no wonder that companies put it off for as long as possible. It gets more complicated as these massive reorganizations have to take place without disruption to ongoing business – so implementing the switch is like walking a tightrope.

Many try and fit it in over long weekends to minimize any down time but often it’s simply not possible without some impact like reduced access. My local bank recently did a network restructuring and they operated on a barebones access mode for 3 full days. They announced it months in advance with frequent reminders. The contact level was clearly aimed at minimizing customer blowback.

Fundamentally, they have to be carefully planned and meticulously executed.

The practicality of the operation is the problem. Organizing the vast number of cables, while ensuring easy access to equipment and maintaining wire and data integrity, presents a gargantuan challenge.

As fiber proliferates these cables have to be treated with kid gloves and cannot be allowed to bend beyond a certain amount because that creates macrobends that harm its ability to transmit data. Yet it all needs to be done with controlled speed. Speed and safety tend to pull in opposite directions.

DTi specializes in wiring and equipment protection, so to help these refits/upgrades, we developed a radius control module (RCM) called Fast-Drop® to prevent over bending and safeguard data flow.

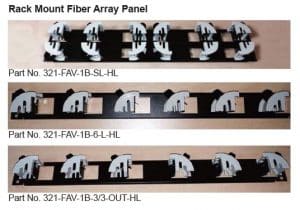

A core goal – in addition to preventing data loss – was to make them as fast and as easy to install as possible. So we came up with a snap-on RCM able to handle any panel edge up to .104” thick. We also built them into arrays in a variety of orientations (see image below) so that wiring can be controlled and managed safely in virtually any rack and wire management configuration.

DTi Arrays for cable management

There are several benefits of using Fast-Drop RCMs for cable management – notably:

- Increased productivity by allowing for rapid modifications of existing racks

- Improved efficiency by keeping cables easily accessible

- Ensured data flow by preventing kinks and macro-bends.

Fast-Drop RCM's attach fast and easily with its patented clip design…or with screws or rivets. They can be used separately as a corner block or together as a fiber spool for control/containment of excess fiber or as a preconfigured array as shown above.

Currently used within patch panels, router racks, switch racks, enclosures, cabinets, and many other systems as it is a fast easy solution for fiber routing applications.

Features:

- Fiber Spool Mounting

- Horizontal or Vertical Mounting

- Impact Resistant to Shock and Vibration

- NEBS/BICSI Compliant

- Flame Retardant – UL94 V-0

- RoHS Compliant

- Hook & loop optional straps

- Available from stock

Watch these short 3-minute videos to learn more about how Fast-Drop can help you prevent data loss and how arrays can help simplify even the nightmare installations.

Find out more about Fast-Drop here.

Request a free sample of Fast-Drop here.