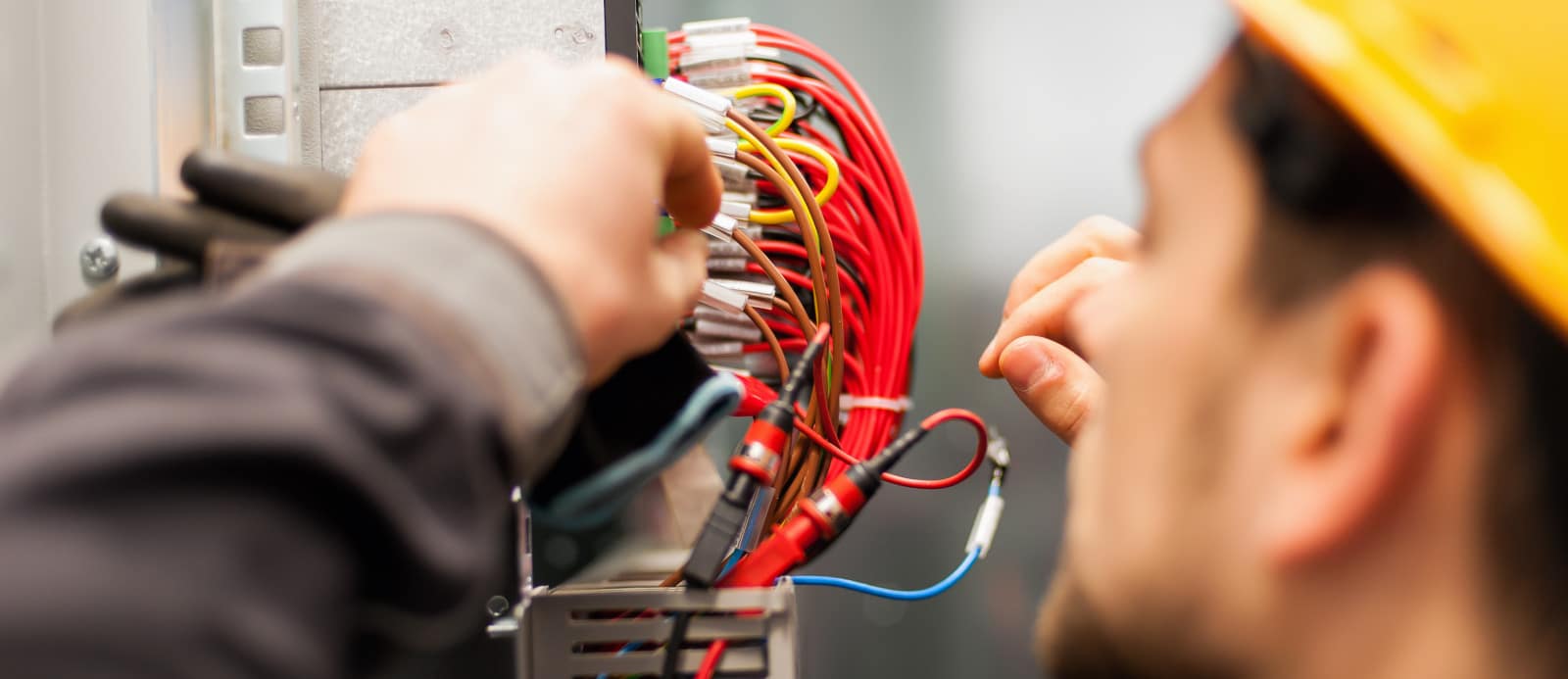

Wire chafing is a common issue that can lead to severe problems such as data loss, functionality issues, and the risk of arcing and fires. This is where caterpillar grommets come into play, protecting wires and cables from chafing and arcing.

In this guide, we'll explain the significance of caterpillar grommet edging in preventing wire chafing and the innovative solutions offered by Device Technologies, (DTi) Inc. to address these challenges.

Understanding Caterpillar Grommets

Caterpillar grommets play a critical role in safeguarding power and data cabling from abrasion caused by sharp edges as they pass through or across sheet metal, rigid plastic, or composite frames.

This protection is essential to prevent the breakdown of the wiring’s electrical insulation, which could lead to a range of operational issues, including data loss, functionality issues, and even the potential for catastrophic fires due to arcing.

Traditional Solutions vs. Innovative Alternatives

Traditionally, simple molded plastic grommets have been used to address wire chafing issues. However, these traditional solutions, such as the old MS21266 or BACG20Z in Nylon or PTFE, come with significant challenges.

The most important challenge is that these grommets lack any intrinsic retentive strength. As a result, they require an adhesive to secure them to the edge. This gluing process is multi-step and highly labor-intensive. It not only takes time but also clearly increases OEM’s costs.

Once in place both the adhesive and nylon grommets tend to degrade over time, become embrittled, and cause the grommet to fall off the edge, which will once again, expose the wiring to chafe. At that point replacing these damaged grommets can be a major problem.

DTi Solution: Spring-Fast® Grommet Edging

DTi’s game-changing solution is Spring-Fast Grommet Edging. It is designed to outperform traditional nylon grommet strips and offer superior wire and cable protection at a lower installed cost and in a fraction of the time.

Spring-Fast Grommets feature a superior encapsulated spring steel core that snaps on with just finger pressure and no adhesive. Importantly it has the intrinsic gripping strength that nylon grommets lack.

This snap-on install reduces installation costs by 49% compared to nylon grommets & enhances efficiency by a factor of 9.5X.

With 9 Spring-Fast Series available, ranging from High Heat to Military Spec, DTi offers versatile solutions to meet wire protection needs across multiple industries, including aerospace, transit/rail/bus, HVAC, food service, servers/data centers, and energy/power.

Example: Aerospace & Military Applications

The Spring-Fast Military Series (M22529) excels in aerospace and military applications where stringent performance standards are non-negotiable. Spring-Fast has been engineered to deliver top performance in both standard and hostile conditions.

The series is Mil-Spec and FAA-approved and is used in a wide range of commercial and military aerospace and DoD applications. These include avionics racks, fuselage edges, ribs, lightening holes, C4 systems, land-based E-shelters, tactical equipment, and DoD missile systems.

Best-in-Class Performance

Spring-Fast has superior edge retention without adhesive, its savings and efficiency gains stem from this significantly faster and easier install process.

DTi ensures that its grommet edging solutions have all the applicable industry standards and approvals, including Mil-Spec, FAA, Navair, FMVSS 302, UL94, FAR25, ASTM, and FDA approvals.

Additionally, the company provides installation tools, including rollers, complete bypass shears, castle removal tools, measuring scales, and go-no-go sizing gauges to facilitate the cutting, measuring, and application of Spring-Fast.

Conclusion

In conclusion, wire chafing can have serious implications for the integrity and safety of electrical systems. Caterpillar grommet edging solutions are instrumental in mitigating these risks and ensuring the reliable performance of wires and cables across applications.

With its innovative Spring-Fast Grommet Edging, DTi offers best-in-class performance, 49% cost savings, and 9.5X efficiency gains, making it the ultimate partner in conquering wire chafing challenges across industries.

Want to find out more? Contact the person who reached out to you.

Order free samples to see for yourself click here.