Spring-Fast Grommet Edging: SL-FST Series

SL-FST is fully encapsulated in a flexible non-halogen, flame retardant,

low smoke, low corrosive, and low toxic TPE for EN 45545-2 FST compliant abrasion protection.

With 4-axis flexibility, it can be used as best in class grommet edging or edge trim.

Key Benefits

- FST compliant for EN 45545-2.

- Stainless steel core fully encapsulated in a flexible non-halogen, flame retardant, low smoke, low corrosive, and low toxic thermoplastic compound for FST compliance and abrasion protection.

- Snap on installation lowers costs 49% vs. grommets with glue. Watch the 4 min. video below.

- Improves efficiency 9.5x – due to fewer steps in workflow.

Grommet Differentiation Table (GDT)

| Grommet Series | Castle Geometry | Flexibility | Polymer Coating | Extra Cushion | 100% TPE Encapsulation | High Heat | Mil Spec | Application Method | Notes |

|---|---|---|---|---|---|---|---|---|---|

| SL-FST | Opposing | Multi axis | Yes | No | Yes | 194°F/90°C | No | Snap on/No adhesive | EN45545-2/NFPA130 compliant No cure time delay |

| FOR REFERENCE | |||||||||

| MS21266 Nylon | Opposing | 2 axis | NA | Yes | NA | 257°F/125°C | Yes | Adhesive Required | 8-24hr cure time delay |

| MS21266 Teflon | Opposing | 2 axis | NA | Yes | NA | 527°F/275°C | Yes | Adhesive Required | 8-24hr cure time delay |

Applications

- Where Fire, Smoke, Toxicity protection is needed – e.g., rail, aerospace, automotive, etc.

- Used on straight, roll formed and flanged edges

- Multi axis flexibility for flanged holes and small radii inside or outside corners

- Also used as a high performance edge trim

Features

The old nylon grommet with glue is old, inefficient, and costly. DTi has a better way.

- 100% encapsulated in a flexible non-halogen EN 45545-2 compliant TPE

- Flame retardant, low smoke, low corrosive, and low toxic

- Best in class abrasion protection

- Snaps on fast with finger pressure – no adhesive

- Installs continuously with multi axis conformity

- Self locking with strong edge retention with no adhesives

- Simpler to install: no adhesive, fixturing, curing, clean up, or OSHA concerns

- Maintenance is far easier due to its ease of application, use, and removal

- Customization available (lengths, colors, and print)

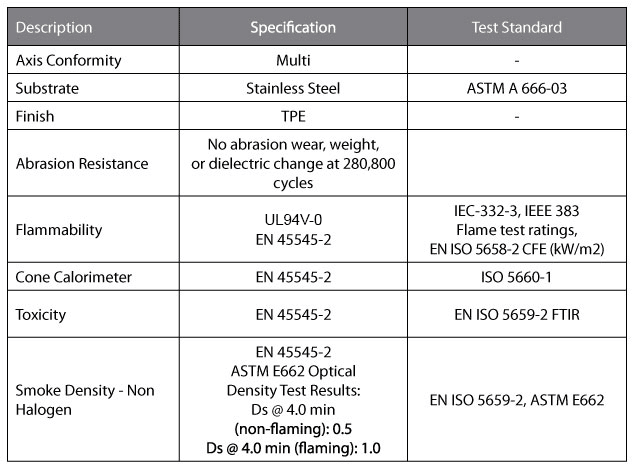

Key Specifications

- EN 45545-2 compliant TPE

- Resistant to hydrocarbons, immersion, salt spray, shock, and vibration

- Operating Temperature Heat continuous to -13°F to 194°F (-25°C to 90°C)

- RoHS and DFARS Compliant

- High gripping strength, corrosion resistance and dielectric strength

- High Shock and Vibration Resistance to rms G 41.7

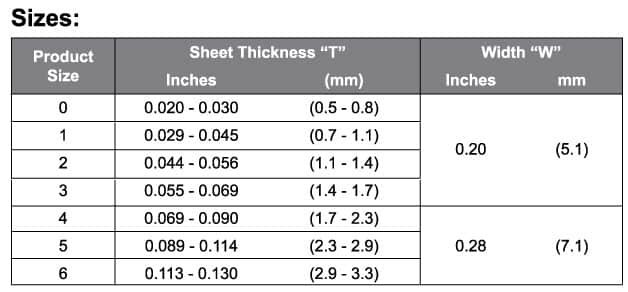

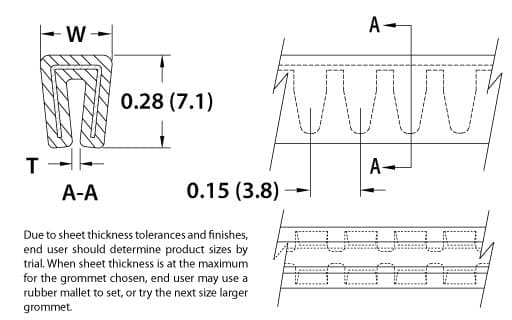

- 7 sizes to fit edge thicknesses: 0.02” to 0.145” (0.5 mm to 3.7 mm)

- Available in custom cut lengths & factory pre-cut reels of 25 ft. (7.6 m), 100 ft. (30.5 m) or 500 ft. (152 m)

- Tools available: Installation roller, full by-pass shears, castle removal, measuring scale,

- go-no go sizing gauge, cutter cart