Seal Application Use Case #201

Use Case: FST Compliant Control System Cabinet for High-Speed Rail

Client: A major OEM of Rail Car pneumatic braking systems

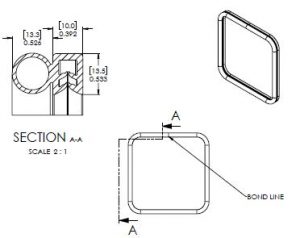

Solution: Seal-Fast Door Seal with Film Bonded Ends – One Piece Assembly

PROBLEM:

- Current rectangular silicone seal used a pressure sensitive adhesive tape (PSA) to fasten to the chassis but it did not bond consistently or reliably.

- It was very difficult to replace properly when damaged because sections of the material and adhesive would remain in places which made refitting slow and costly.

- Material and PSA tape was not tested and approved to meet Flame Smoke and Toxicity (FST) requirements.

- Water leaks were common at the seals terminating ends which required repair and a slow, messy adhesive application on site – making damaged sections even more difficult to replace.

SOLUTION:

- Seal-Fast™ FST Silicone edge mount bulb door seal

- Pre-joined terminating ends one-piece application

- Solved the bonding and leakage

- Passed the IPX6 rating per IEC-60529- 3-minute water spray over the entire box at 100L/min.

- Meets the FST requirements laid out by ASTM

SIGNIFICANT BENEFITS

- Easy application with finger pressure with no adhesives

- Saves time and money with quick assembly

- Metal substrate gives it “aerospace standard” grip strength

- 100’s of profiles are available

- Made in the USA

For more information on Seal-Fast Silicone Door Seals go here

Request Free samples here