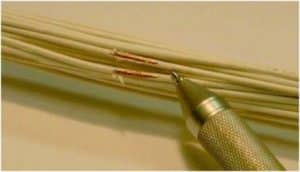

During your ADS-B install, take the opportunity to inspect and protect the aircraft’s critical EWIS against chafe induced arc, spark, and combustion. Close inspection on the ground is warranted as forces created by flight can cause cable, harnesses and lines to shift and chafe.

Image courtesy of Egyptair

Congratulations – Your ADS-B Refit Is Happening

After months of research, you have finally selected the “best approach” STC for the ADS-B compliance mandate, you've scheduled the installation well within the mandate time frame; so by any account, you should be good-to-go……or are you?

But have you thought about inspecting that all-important EWIS?

If your airplane is 15-20 years old or older, this is an opportune time to inspect ALL the wiring for signs of chafing, worn or comprised insulation, carbon track or wet arcing, clearance to adjacent structures, fluid lines, and flight control cables.

While the basic air frame is robust and resilient, in flight, it is subjected to aerodynamic loads which cause it to bend and twist. Furthermore, engines, propellers, and by-pass fans transmit vibration while vertical gust loads and moderate turbulence can create excitations as high as 2.5 to 3 G's.

Because aircraft bend and twist under the stress of flying, a static ground inspection in the hangar doesn't guarantee wires won't rub against other components once in the air.

A fuel line can be two inches from any adjacent structure or component but once off the ground that same line could be rubbing and chafing against the plane body or other components.

Although airplane manufacturers generally provide protection for certain critical electrical circuits, there is no FAA regulation that specifies wire separation criteria or identifies which circuits must be protected.

The closest to a policy may be the FAA’s initiative requiring zonal inspections of all EWIS within 2” of structure or flight critical wiring circuits, and hydraulic or pneumatic lines.

- EWIS must be designed and installed with adequate physical separation from fuel/hydraulic/oxygen/water/waste lines and other fuel/hydraulic/oxygen/water/waste system components, so that: (1) A EWIS component failure will not create a hazardous condition. (2) Any fluid leakage onto EWIS components will not create a hazardous condition.

- (c) Wires and cables carrying heavy current, and their associated EWIS components, must be designed and installed to ensure adequate physical separation and electrical isolation so that damage to circuits associated with essential functions will be minimized under fault conditions.

Per the FAA guidelines and in the interest of flight safety, DTi recommends that the following precautions/actions be taken concurrent with the ADS-B equipment installations, and all subsequent EWIS zonal inspections:

- Protect against chafing – wires /cables passing through penetrations in air frame and within 2 inches of adjacent structure members with Spring-Fast® Protective edge grommets.

- In addition, consider protecting wires bundles and cable assemblies having less than 2 inches of static clearance between or at harness junctures with Protect-Fast™ Braided protective sleeving.

Spring-Fast eliminates chafe induced arc, spark, and combustion. It has been providing best-in-class EWIS anti-chafe protection since 1984 – at half the install cost of legacy systems.

How DTi's Grommets Can Help

This install and opening rarely exposed compartments gives you and your MRO a perfect opportunity to inspect/replace/install grommets to protect the EWIS and avoid equipment discrepancies – which are often traced to wiring problems rather than equipment issues.

DTi’s Spring-Fast best-in-class grommets install for 50% of the cost of the old slow legacy nylon grommets with glue. They install in a 1/10 of the time with finger pressure. Minimal inspection. No fixturing. No curing.

Spring-Fast Mil Spec M22529/2

This best in class EWIS protects against chafe induced arc, spark, and combustion.