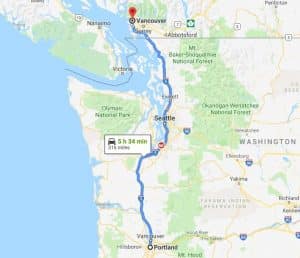

The governments of Washington state, Oregon, and British Columbia – plus Microsoft – have come up with an ambitious report that proposes a 310 mile high-speed rail line to connect Portland and Vancouver.

The report outlined the need for more transportation infrastructure investment in the Cascadia megaregion. Crowded roads, congested airports and limited intercity rail service limit residents, businesses and tourists. Vancouver, Seattle and Portland have the 4th, 6th and 10th most congested roads in North America,

To compound the problem, airport delays are making air travel increasingly unreliable, and the travel time and frequency of intercity rail service (Amtrak) are not competitive for most trips.

It will only get worse. Portland/Seattle/Vancouver are projected to add 3.5 million residents by 2040. Roads like the I-5 corridor will only get more congested over time. The report estimates that adding a lane to the I-5 – both ways – will cost $108 billion.

The train could travel the 310 miles in 2 hours – reaching 250 mph at times. That is clearly far quicker than driving. Heck, the Seattle – Portland commute could be less than an hour.

Huge is the word for this project.

Initial cost estimates come in at $24 to $42 billion. For comparison, the Big Dig (the massive highway project in Boston) cost just over $24.3B. If I were a betting man, I’d say this project will end up at the higher end of that $24-42B range.

The estimated economic, traffic and environmental benefits are equally as significant:

- Estimate $355 billion in economic growth and 200,000 new jobs related to construction and ongoing operations.

- Reduce intercity traffic by 12-20% – reducing carbon emission, crashes and deaths.

- Over the first 40 years, it can cut 6 million metric tons (tonnes) of CO2 emissions.

- Potential for zero emissions by using clean energy sources like hydro, wind, solar.

Short term, the analysts think the line could generate $250 million in revenue within five years of opening.

There is plenty still to talk about – not least who pays for it! A study group has been tasked with the next steps. If everything goes according to schedule, rides could begin in 2035.

DTi can save the planners and rolling stock builders time and money. Two examples:

Spring-Fast® grommet edging: prevents data loss from wiring chafe on rolling stock. It replaces the old glued nylon grommet – by delivering best in class performance with 49% lower install costs & improving efficiency by 9.5x. This is driven by the highly effective self locking nylon clad metal substrate design that snaps on with finger pressure, eliminating the old slow and costly multi-step glue process.

* Seal-Fast seals protect equipment on trains by keeping out heat, cold, water or dust. Its single piece construction snaps on easily with strong edge retention. Hundreds of U.S. produced commercial off the shelf profiles available in PVC/EPDM, EPDM, Silicone with/out a steel substrate.

Read an executive summary and the full report here

To read: “How Wire & Equipment Protection is Making Inroads into the US & EU Rail Transit Market” go here