Covid has posed significant challenges for mass transit.

The ridership effect has been dramatic: the first half of 2021 vs. 2019 saw significant declines in ridership: Washington DC -85%, San Antonio -50%, Boston MBTA -70%, and San Francisco MTA -88%.

It’s easy to understand why if you have ever experienced a pre-Covid rush hour on a mass transit system.

By their very nature, mass transit systems involve masses of people huddled together in small spaces and in much closer proximity than in buildings where people can maintain some level of social distancing.

Scientists agree that the SARS-CoV-2 virus can be transmitted through droplets emitted when a person breathes, talks, shouts, sings, coughs, or sneezes. Larger droplets fall to the ground or onto surfaces quickly due to gravity but smaller droplets or aerosols can remain airborne for longer periods. Small enclosed spaces make this more of a threat.

Making transit safe and communicating the safety processes and protocols in place to riders is key to getting back to “normal” and helping the economy return to pre-pandemic levels.

Passenger Safety Concerns about Indoor Air Quality (IAQ)

Riders on transit feel threatened by Covid as buses and carriages are small enclosed spaces where virus aerosols could be in the air so an effective IAQ strategy is important to mitigate the risk -although it has to be said that any strategy cannot eliminate it entirely.

Transit systems are tackling this issue by assessing the current IAQ of their equipment to get a better understanding of current airflows and the possible risks. The plan is to increase safety by deploying IAQ technology and then monitoring the IAQ using sensors through the different cycles of occupancy. It’s not a simple process.

Technology is being deployed in 3 core directions to mitigate the transmission of pathogens.

- Dilution & Exhaust. You bring more fresh air in while sending indoor air out as both will dilute the virus. In buses, this occurs somewhat naturally as doors open and close regularly but it is hard to rely on a mechanism that is not consistent enough to be truly effective even though it can be enhanced by an HVAC/air handler system. Regardless it doesn't solve the issue of contaminated surfaces, can also increase energy use, and decrease the system's efficiency, especially of electric buses.

- Containment. This is essentially managing indoor humidity as it can support the growth of surface and airborne microbes. The goal is to keep the relative humidity levels within recommended ranges that will reduce the incidence and risk of microbes while also balancing rider comfort.

- Cleaning. A wide array of technology is being considered: filters, ultraviolet germicidal irradiation (UVGI), bipolar ionization (BPI), photocatalytic oxidation (PCO) – both traditional and graphene-enhanced, and dry hydrogen peroxide (DHP) generators. Clearly, the level of complexity involved with IAQ post-Covid has increased dramatically.

The challenge here is that there will always be an element of risk. You cannot hermetically seal buses and carriages so these systems and technology are all about mitigation. However, at this point, there are numerous IAQ products that span a wide range of technologies, properties, and performance. The newness of the field means there are no real standards. It cries out for some level of standardization for performance levels around safety, suitability, and efficacy. For example, we can’t solve one problem by putting passengers at risk from another avenue- like UV light. It's effective but it's not safe or suitable. A balance needs to be struck.

Impact of IAQ Improvements on Transit Systems

The pandemic will push transit systems toward better IAQ systems and that will likely involve new designs and refits.

The ridership decline will take some time to recover and it may only do so after the new protocols and IAQ systems are known to be in place. Transit systems have to regain rider trust.

Fewer riders mean less revenue and higher costs for IAQ will affect budgets. The reality is that transit systems will have to do more with less. They will need cost savings and efficiency in all areas: new equipment, refits, builds, and repairs. There will be a knock-on effect throughout the transit supply chain as they push OEMs for better prices.

So the pressure will be on for transit systems and their suppliers to squeeze out every last drop of savings and efficiency– all while maintaining high levels of safety and efficacy.

DTi Can Help

DTi supplies components to OEM’s that make the transit vehicles and supporting infrastructure. As new IAQ systems are installed or built from scratch, we supply the grommet edging, window and door seals, wall panel edge trim, cable waterfalls, and protective sleeving that can create much-needed savings and efficiencies in their manufacturing.

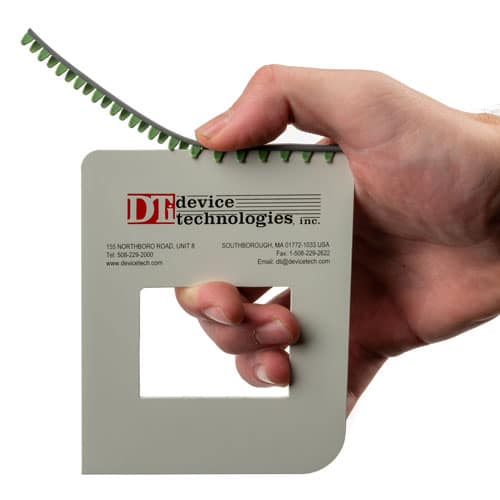

As an example, OEMs can cut one component cost in half by using Spring-Fast® Grommet Edging rather than glued in grommets. Spring-Fast protects wires and cables from chafing and arcing with best-in-class performance, a snap-on installation that lowers costs 49% and improves efficiency 9.5x – due to far fewer steps in the install workflow.

Spring-Fast Grommet Edging

Seal-Fast Edge Seals

Seal-Fast Edge Seals offer a better faster way to protect your data, services, and equipment from environmental conditions such as dust, fumes, heat, cold, and moisture. They snap on quickly and securely, for an effective seal solution.

For more information on Spring-Fast® Grommet Edging go here

For more information on seals go here

See for yourself … get free samples go here