Sikorsky Savings

Current production specs for the CH-53K detail the legacy nylon grommet MS21266 for anti-chafe and anti-arc protection. It requires a slow, multi-step install that is both time-consuming and costly.

An alternative is Spring-Fast grommet M22529/2 which applies simply and quickly with finger pressure. We estimate that switching could save Sikorsky $3.338 million over the life of the CH53-K program. The details are below.

The Insignificant Grommet?

While grommet edging is a small component of any aircraft; its impact on the EWIS is far larger than its size. It protects aircraft wiring from chafe that can result in arcing, sparking, and fires. However, chafe creates a far bigger more low-level issue than extreme cases of arcing and sparking.

NAVAIR research shows that when aircraft are designated as AOG (Aircraft on Ground) or NORS (Non-Operational Ready Status), the biggest single reason – 37% – was wiring discrepancies due to chafe. Chafe is a significant drag on readiness, availability, and efficiency – for military or commercial aviation.

Assumptions

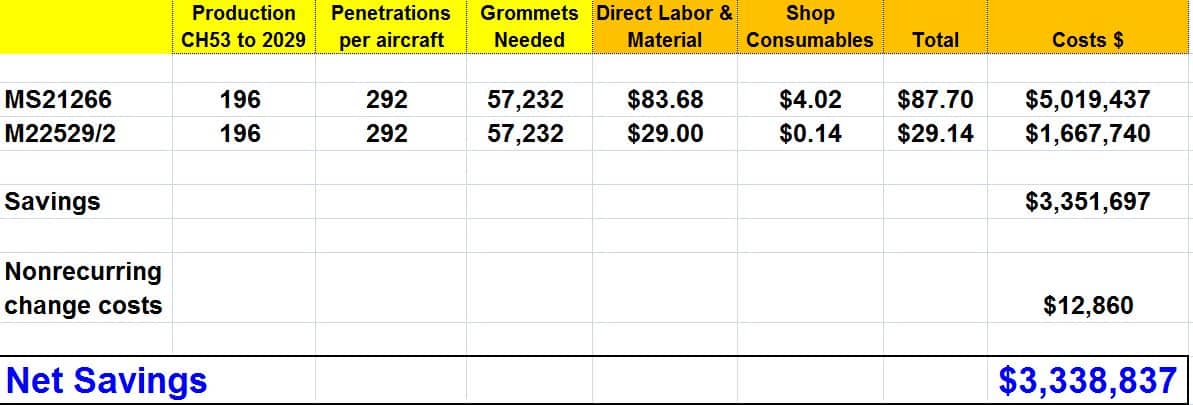

Our cost analysis is based on a trade study format. For the CH-53K, it assumes: 196 are produced through 2029, 292 penetrations per aircraft, a wrap rate of $200, and an NRE of $12,680.

The table below shows the top-level breakdown of the costs and savings: direct labor and materials, WIP consumables (safety glasses, Scotch-Brite, wipes, cheesecloth, etc), and nonrecurring costs for the change.

M22529/2 already has NAVAIR approval and is fully qualified as an FAA-approved replacement part.

Why the Savings Are So Significant

Key features of the M22529/2 drive a far lower direct labor install cost:

- Snap-in-place installation without adhesive

- Superior retentive strength without adhesive

- Immediate wire/harness routing – no fixturing or cure time delays

Issues with the Old Legacy MS21266 Grommet

- Preparation and application is a multi-step process.

- Multiple items for application & technician safety have to be collected before installation.

- Edge prep is needed: light abrasion with Scotch-brite & cleaning with IPA or an acetone wipe to ensure proper adhesion.

- Nylon grommets have no inherent retentive strength and tend to straighten and disbond, so are glued to an edge using Pliobond –a single-stage, MEK solvent-based, air cure adhesive. While Pliobond is considered a contact cement, in almost all cases, MS21266 requires “fixturing” – pieces of masking tape hold it in place until the adhesive cures.

- Any excess adhesive after curing has to be cleaned with a MEK solvent and elbow grease.

- Disbonding means the work often has to be redone adding to the cost of poor quality.

This may have been state-of-the-art when the S-56 was being built, but now it is an anachronism.

M22529/2 –The Better Way

- M22529/2 is a high-performance grommet that has a polymer coating on an ultra-thin CRES substrate that snaps into place with finger pressure.

- It is a caterpillar-style grommet with opposing finger-like castles that exert a compression force that creates static friction for retention without glue.

- It has passed 20/20/20 G static load tests even when 4 castles are removed to provide clearance for a p-clamp riveted clip used on some penetrations.

- M22529/2 also virtually eliminates the large FOD footprint of shop consumables (gloves, cheese cloth, adhesive, tape) required for the glued nylon grommet.

This single-component switch offers significant multimillion $ savings, improved efficiency, and best-in-class performance.

Indeed recently we had a specification success when after several weeks of testing similar products; Sikorsky Aircraft approved an EC (Engineering Change) mandating the use of M22592/2 on specific fittings subjected to severe vibration on the US Army UH-60M program – a testament to the product's high performance.

Find out more about Spring-Fast here